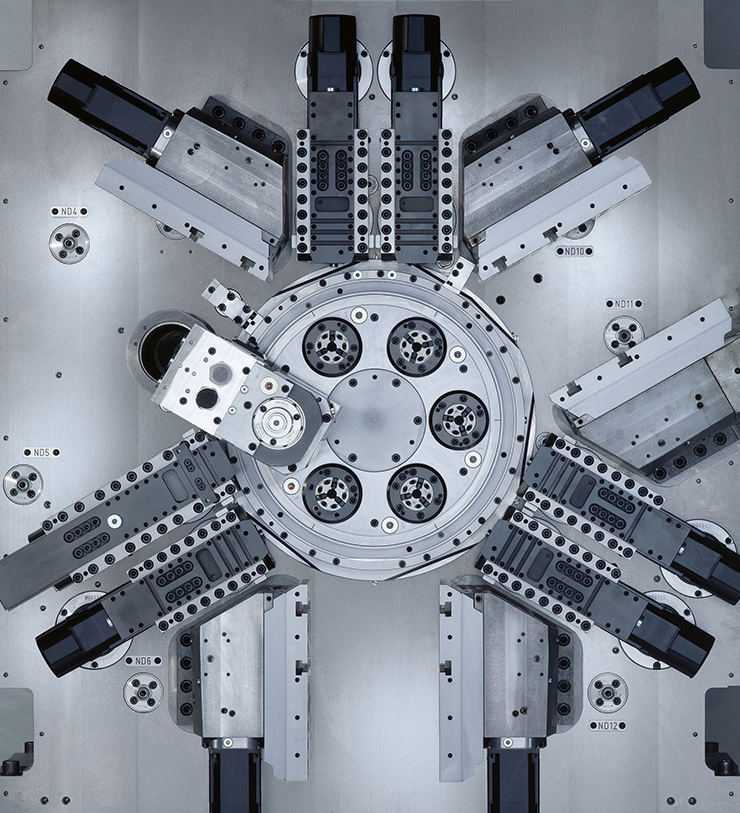

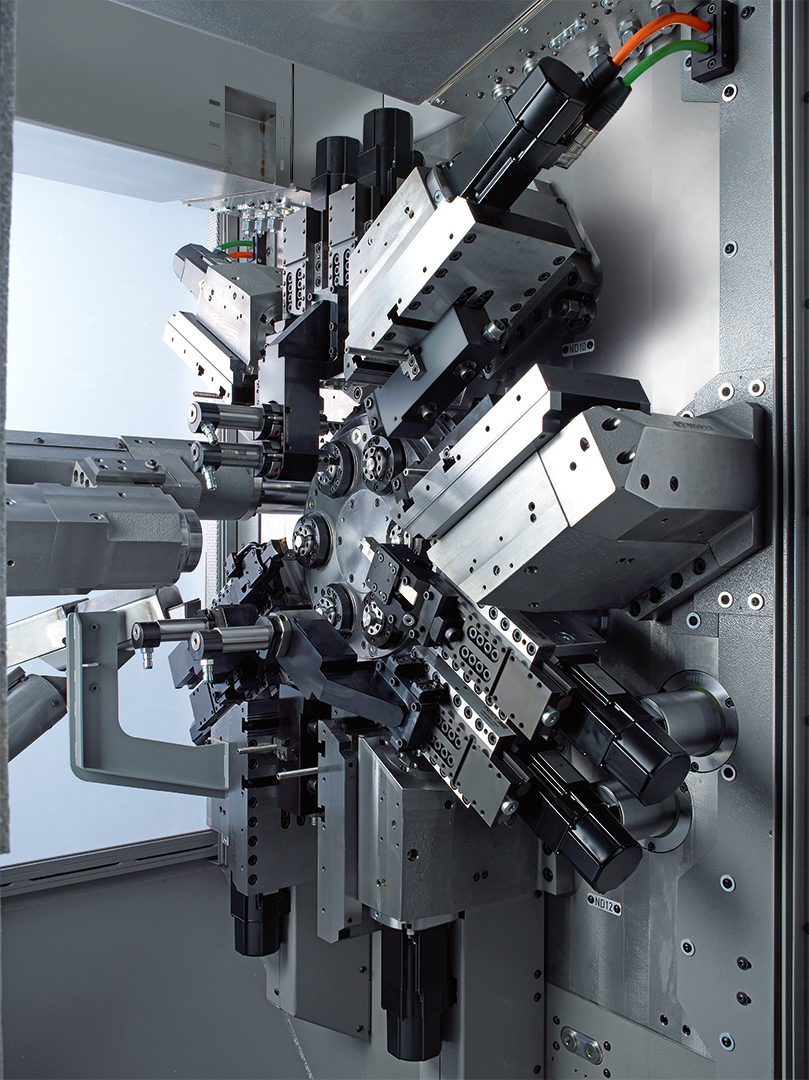

Dynamic multi-spindle lathe

Shortest possible changeovers, ultra-high dynamics and lowest secondary times are the basis of minimal cost per part.

Machine highlights

Your benefits

-

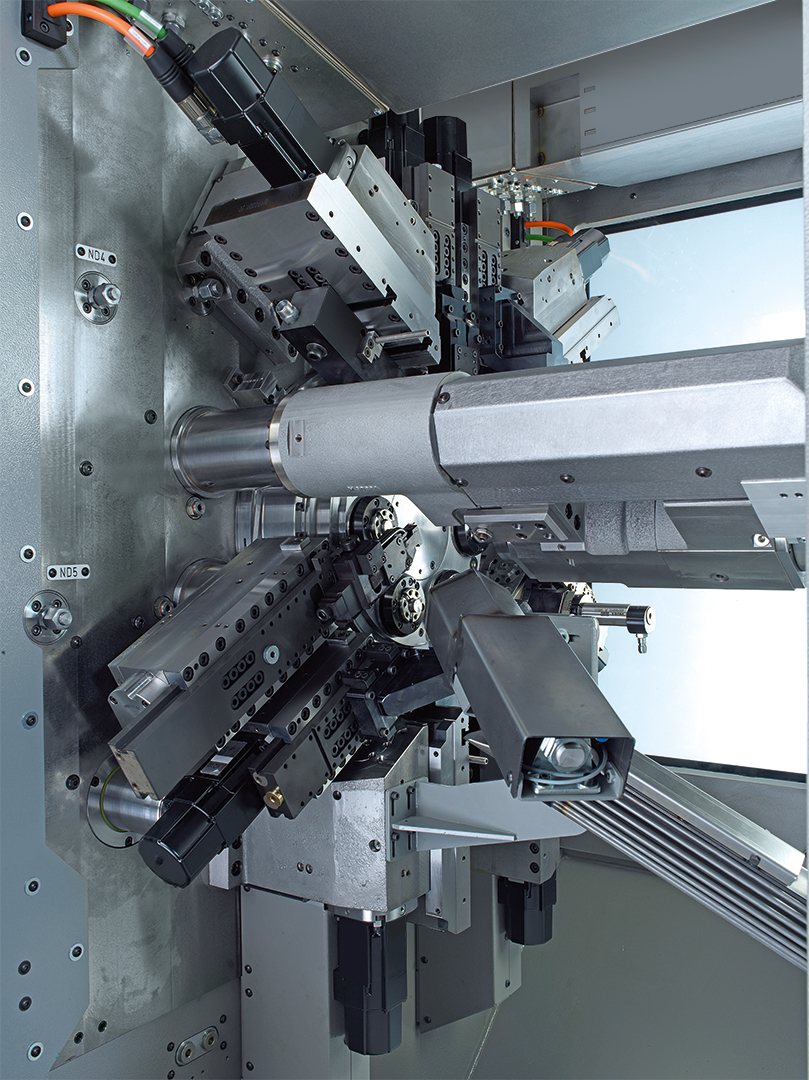

Grooving slide for maximum cutting performance with minimum machining time

-

Quick tool setup by INDEX W-serration

-

Spindle drum with individual drives of the work spindles

-

Cross-slide for flexible complete machining

-

CNC cutoff slide with extended stroke for rear end machining

-

Highly dynamic synchronous spindle with extremely short acceleration and deceleration times

-

Up to 22 mm bar diameter with version MS16 Plus

-

Already included: the operating system Xpanel i4.0 ready with 18.5” touch screen and INDEX C200 sl based on Siemens S840D sl

MS16 in focus

Configuration as a single synchronized machine

• Synchronized spindle in position 6.1

• Cutoff and rear end machining slide in position 6.2

• Grooving or drilling slide

1x selectable per spindle position (1 to 5)

• Extension version with separate cutoff slide 6.0 and pure

rear end machining slide 6.2

• Cross slide 1x per spindle position (1 to 5 selectable)

Configuration as a double synchronized machine

• Synchronized spindle in position 5.1/ 6.1

• Cutoff and rear end machining slide in position 5.2/ 6.2

• Grooving or drilling slide

1x selecabe per spindle position (1 to 4 selectable)

• Extension version with separate cutoff slide 5.0 / 6.0 pure

rear end machining 5.2/ 6.2

• Cross slide 1x per spindle position (1 bis 4)

The machine design

With dynamic and diverse machining capabilities at low unit costs

-

A maximum of 12 tool carriers with 1 or 2 travel axes

-

Fast synchronous spindle for rear end machining

-

Several tools per cross-slide possible

-

Variable use of tool carriers, internal-external, stationary or live

-

C-axis machining possible in every spindle position

-

Polygon turning and other machining options

Extended version MS16C Plus

Diverse machining technologies

Milling

Milling with live tool, also in conjunction with C-axis mode (Transmit).