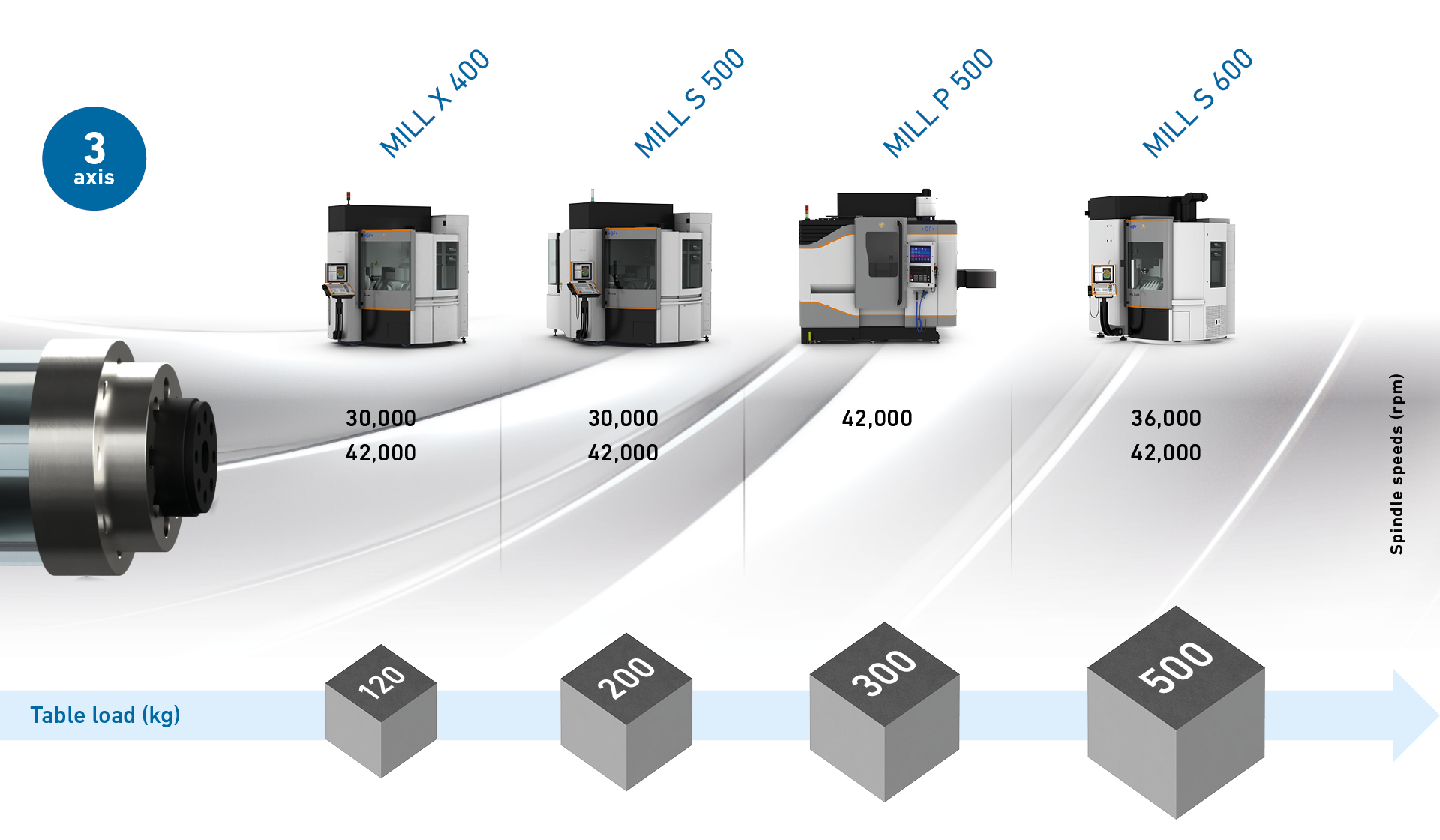

3 & 5 Axis Mills from Mikron offer higher feed rates with up to 42,000 rpm and achieve surface finishes finer than 0.1 µm.

Milling

What is Milling?

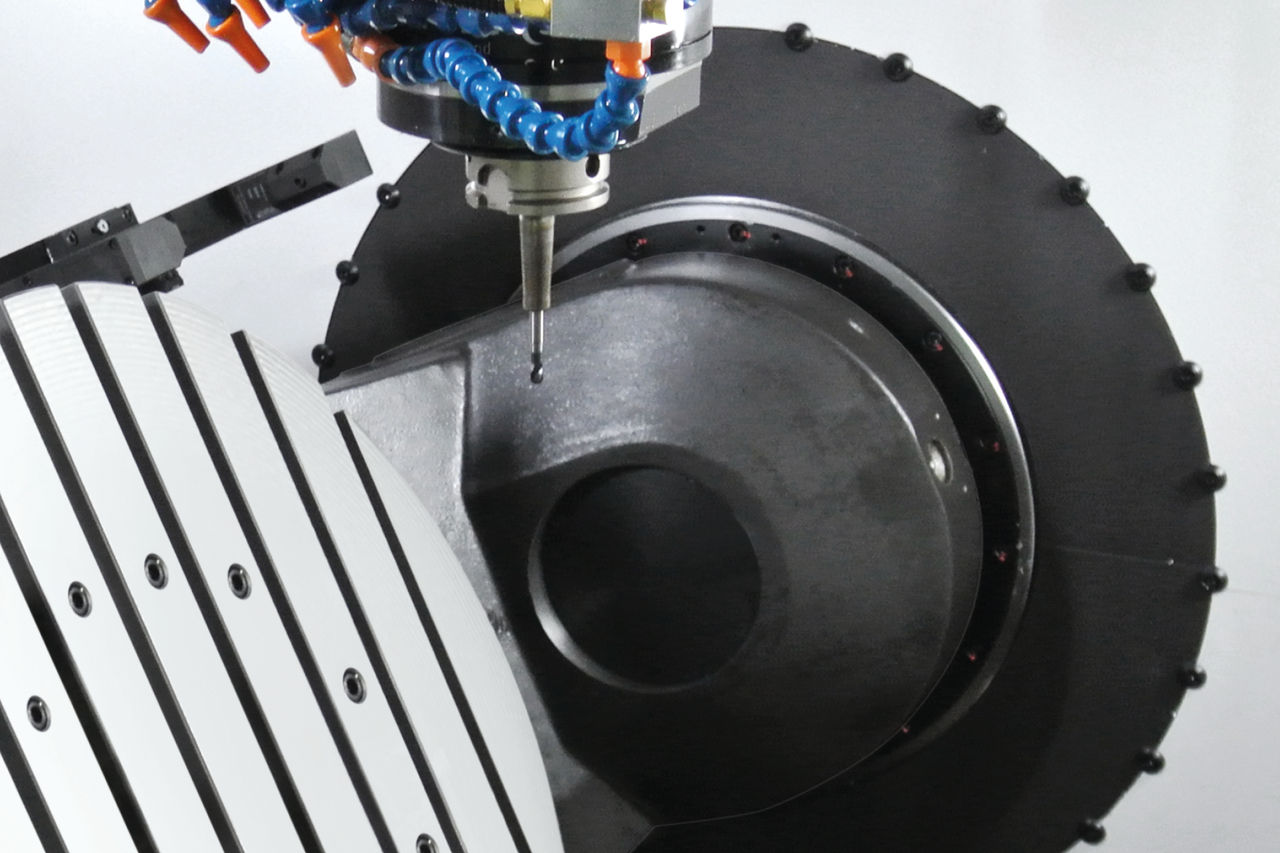

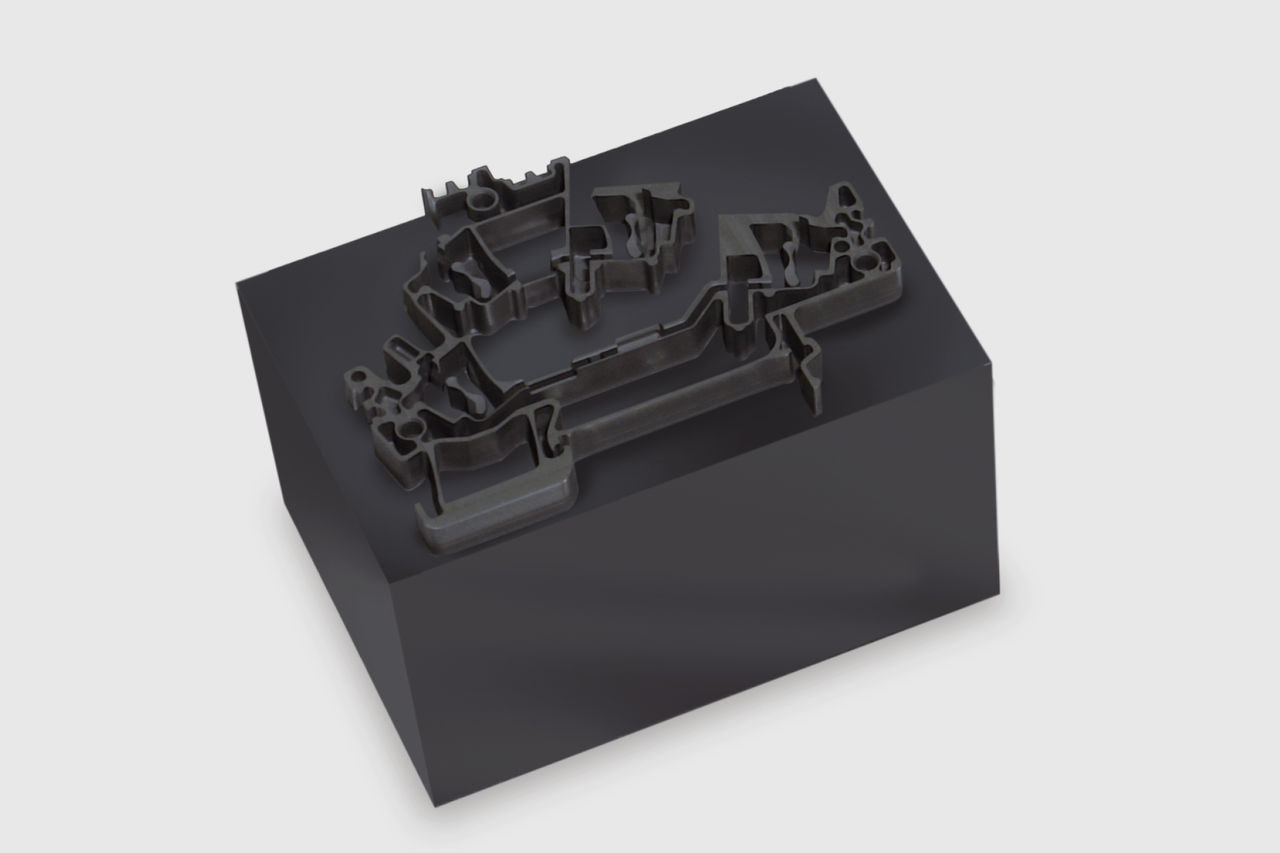

A highly efficient process used in manufacturing and material processing, Milling involves the use of rotating spindles to grind and remove material into smaller particles from a blank part, achieving desired shapes and dimensions. It is a technology of choice for creating components with exceptional accuracy and surface finish.

Why come to GF Machining Solutions for your milling application?

Specializing in vertical milling machines and with a customer-oriented approach, GF Machining Solutions’ Milling portfolio includes machines in three and five axes, allowing the handling of various part complexities. Discover what you will find with our Milling machines!

Main competitive advantages

Watch the videos of our competitive advantages

AMC

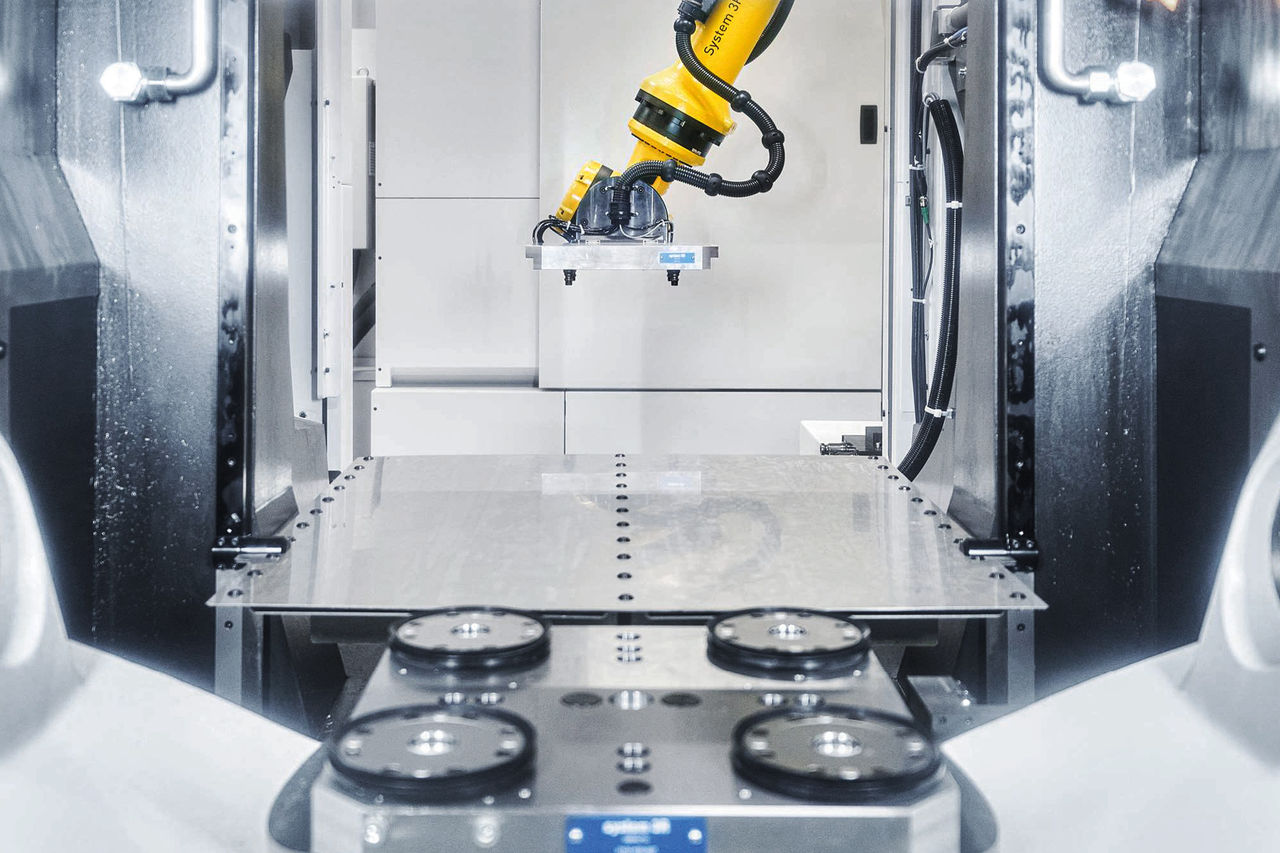

Automation

MSP

Linear and torque motors

Overview of the series

Our range of Milling machines

0-500 kg 3 axis

500-1500 kg 5 axis

0-600 kg 5 axis

600-4000 kg

Should you need to machine small parts for the medical industry to extra large parts for aerospace applications, find exactly the machine that fits your workpiece requirements:

3 axis / 0-500 kg

3 axis / 500-1500 kg

5 axis / 0-600 kg

5 axis / 600-4000 kg

Application possibilities

Liechti Engineering

Offering solutions for the aircraft engines and the energy generation sectors, our Liechti Engineering division is the worldwide market leader for five-axis airfoil machining solutions, for the turbine industry in aerospace and power generation. Full turnkey solutions from one single source help you to meet your quality and quantity production targets.

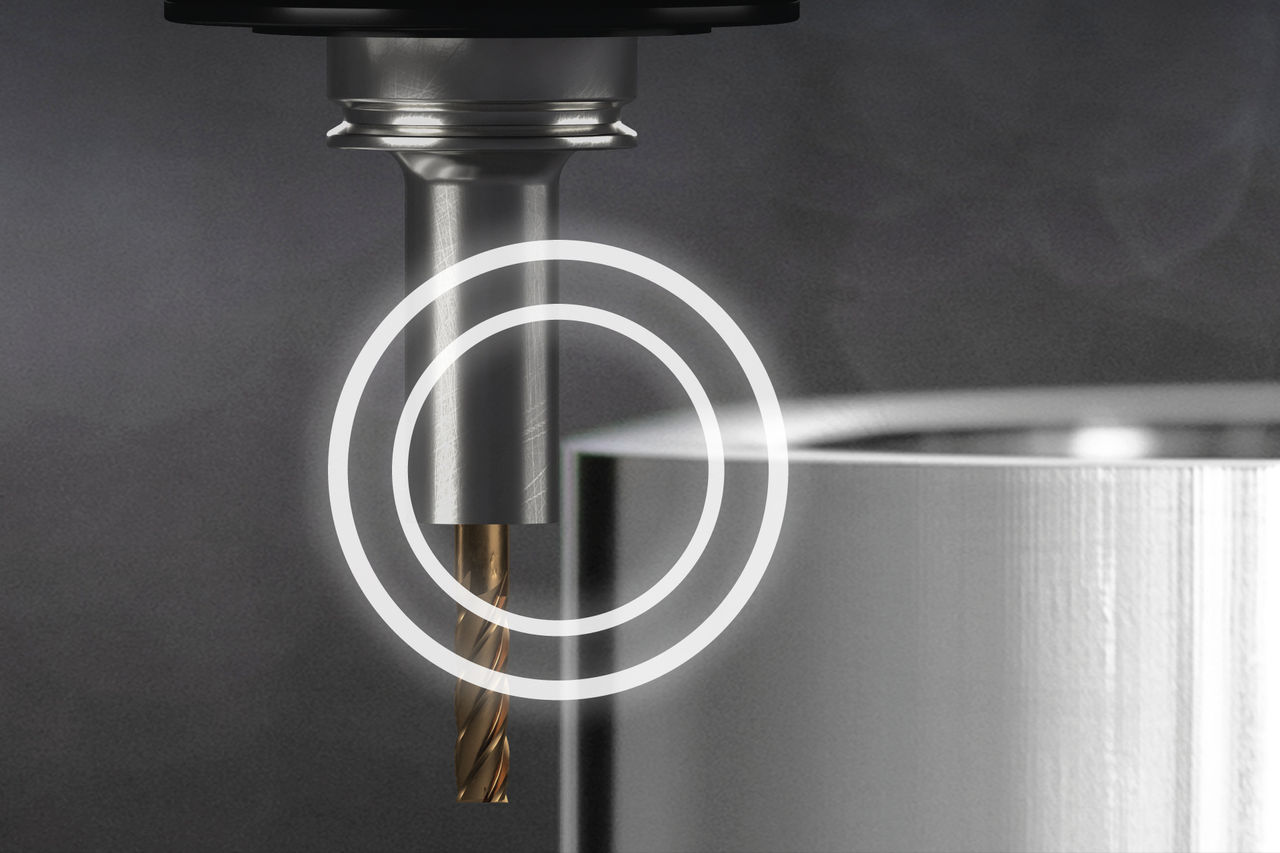

Step-Tec Spindles

Our high-quality Swiss-made Step-Tec Spindles are designed and assembled directly on our Milling machines within our Biel facility.

Application

Whether for Grinding, Milling or Turning, our solutions and innovations are ready to meet your requirements.

Spindle platforms

A comprehensive range of CNC motor spindles with the speed, power, performance and dynamics that machine manufacturers require.

Expertise

Incorporating Industry 4.0 best practices and intelligent solutions, Step-Tec offers outstanding spindle monitoring expertise.

Services

Taking advantage of a global network of repair centers, Step-Tec helps you and supports you for service at its best.

Energy efficiency

With a reduction of 7 to 17% of the daily energy consumption compared to the previous generation, our new generation of Milling machines is ready for the future. This important improvement is possible thanks to the highly efficient exhauster system that reduces the usage of compressed air and to Intelligent Temperature Control that compensate any temperature fluctuations.