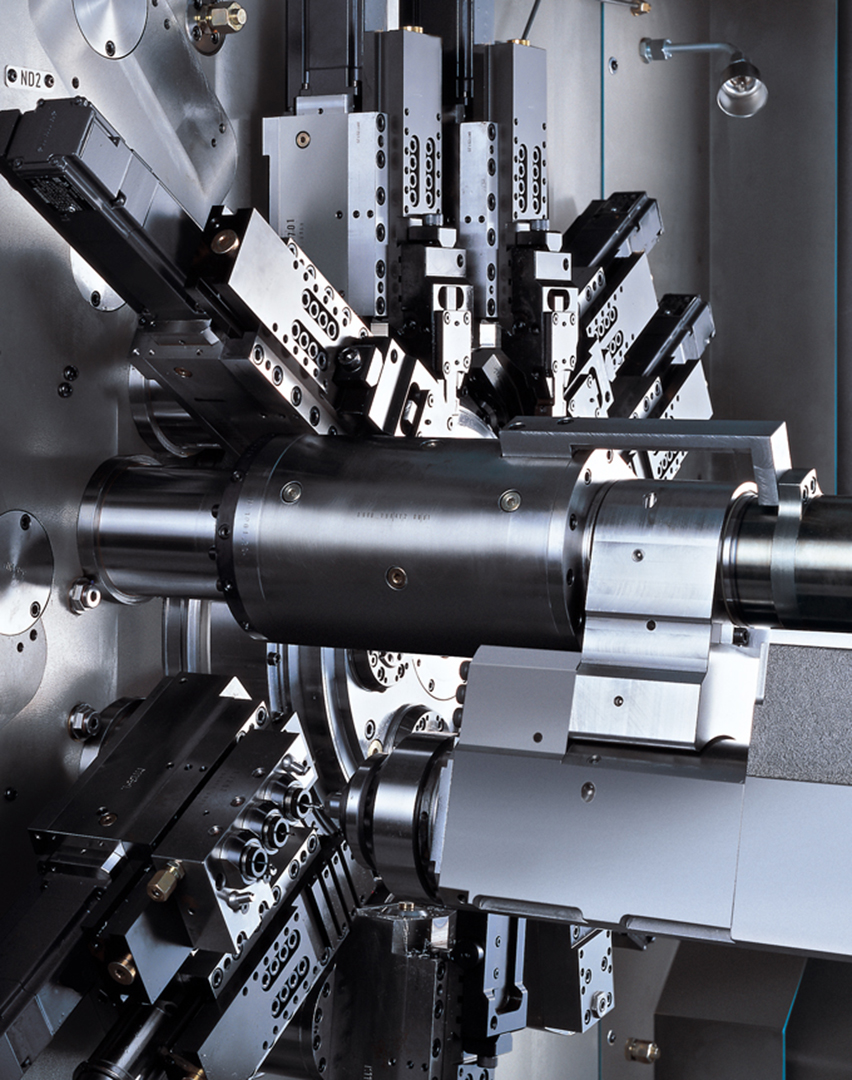

Front open multi spindle machine for bar turned parts

Precision, speed and flexibility

Machine highlights

Your benefits

-

Front-opening machine for bar machining

-

Freely accessible and thus extremely user-friendly

-

Highly-dynamic slides with sliding guide (X-axis)

-

Non-wearing Z-axis due to quills with hydrostatic support

-

Extremely fast synchronous spindles

-

Maximum of 6 tools for rear end machining

MS22 in Focus

Machining options

The work area offers extensive machining situations per spindle position.

The typical INDEX machine features a tool carrier arrangement in the work area without a sliding block, which allows more than one tool to be used on each spindle. The possible machining operation is thus limited only by the tool holder. As a result, you can specify all production steps in almost all spindle positions. Another advantage: You have an open flow of chips.

Maximum productivity and economy of multi-spindle automatics combined with the precision and flexibility of CNC single-spindle automatics is what makes the MS22C multi-spindle automatic so successful.

For a wide variety of procedures and for complete machining

-

Coupled with electronic precision

-

Requirements with maximum stability

-

Toothing in correct position relative to other surfaces or shaped elements

-

Any angular offset can be programmed

-

Greater tool service life due to shifting with Y-axis

Milling

Milling with live tool in the following variants:

-

Side milling cutter in conjunction with C-axis operation (transmit function)

-

End mill in conjunction with Y-axis mode

-

Plunge milling

Elliptical deburring of cross-drill holes

Uniform deburring (even chip removal) of cross-drill holes based on interpolation of the C-axis, X-axis, and Z-axis with live tool